Build concrete that meets Highland Park's climate demands and code requirements. We properly grade for drainage, thoroughly compact subbases, and install air‑entrained, low w/c mixes with fiber reinforcement, proper joint spacing, and adequate coverage per ACI/IDOT standards. Rely on premium freeze‑thaw durability, salt-wear prevention, and safe-traction finishes for all concrete installations from driveways to patios. We take care of permits, certified plans, inspections, and detailed timeline management, complete with documented mix designs, pour tickets, and RFIs. Our repairs and overlay work follows strict testing Highland Park best Concrete Contractor protocols and curing procedures. Discover how our comprehensive process protects your investment.

Important Insights

- Local Highland Park experts: oversee permits, inspections, and local regulations, delivering approved technical drawings and detailed weekly updates on progress, safety, and quality.

- Durable, weather-resistant concrete: featuring air-entrainment systems, optimized w/c proportions, mineral additives, proper curing techniques, freeze-thaw protection and salt attack mitigation, and ultraviolet-stable, slip-resistant coating systems.

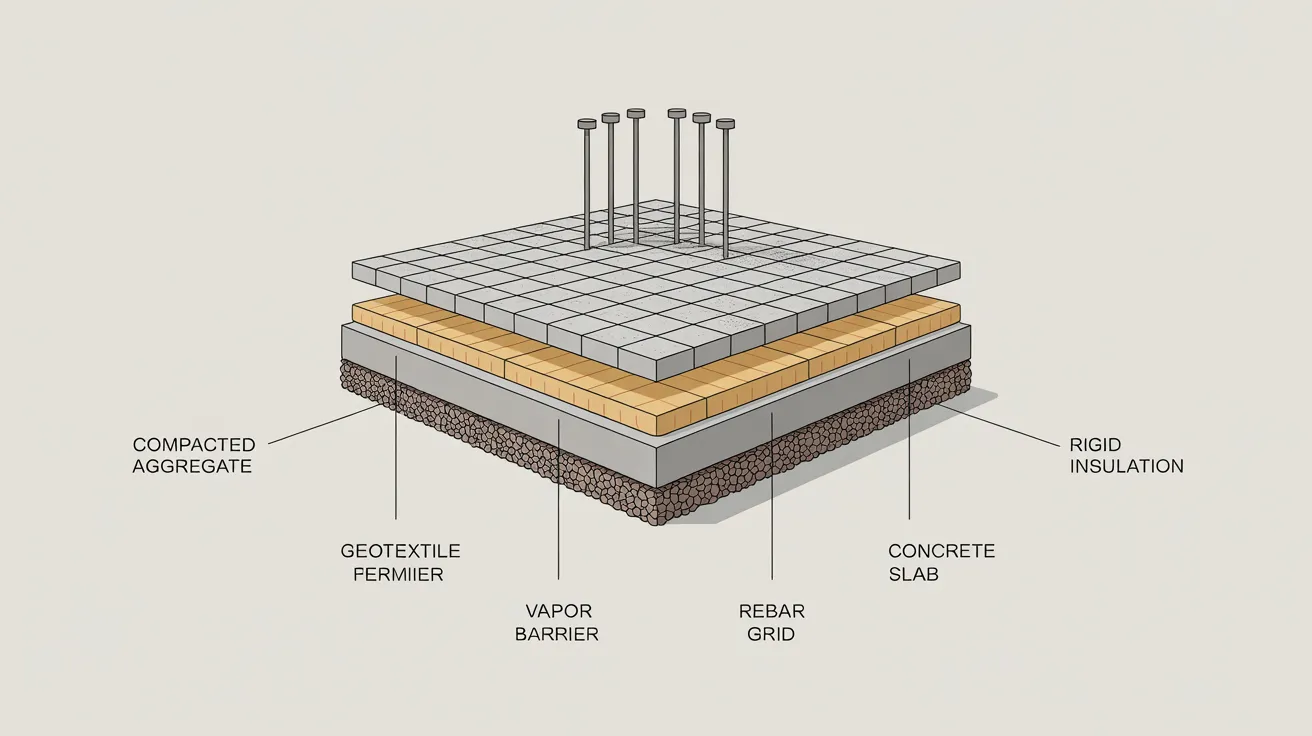

- Accurate site prep and drainage: validated elevations, 2% slopes, compacted subgrade, geofabrics, moisture membranes, and utility/easement mapping to avoid settling and dampness concerns.

- Strong, code-compliant slabs: reinforced with #4/#5 rebar, properly placed joints meeting ACI/ASTM requirements, appropriate concrete cover, structural connectors, and temperature barriers to minimize structural movement and heat transfer.

- Clear schedules and costs: You'll have access to comprehensive Gantt charts and timelines, up-to-date weather conditions and inspection notifications, itemized estimates broken down by quantity and unit rates, and shared logs for project tracking including change orders, submittals, tickets, and information requests.

The Importance of Local Knowledge in Highland Park

Though concrete standards are the same across regions, Highland Park's climate, soil profiles, and municipal codes require local knowledge to construct properly the first time. You need a contractor who interprets expansive clay, understands freeze‑thaw cycles, and selects mixes, reinforcement, and jointing that fulfill local performance criteria. With neighborhood knowledge, a professional maps drainage patterns, utility easements, and right‑of‑way constraints that impact slab thickness, base prep, and placement timing. They also streamline permit navigation, processing stamped plans, coordinating inspections, and aligning work with Highland Park ordinances and IDOT references. You'll eliminate delays, rework, and violations because details like air‑entrainment, curing windows, and salt‑exposure mitigation are handled up front. Local expertise converts code into constructible solutions-on schedule, as planned, and prepared for review.

Driveway Design and Installation

First, tackle site grading fundamentals to handle proper water flow, frost protection, and required gradients. Next, you select appropriate reinforcement-fiber, rebar, or welded wire mesh to prevent cracking and accommodate vehicle loads per local specifications. Lastly, select finishes—sealed smooth, broom, or exposed aggregate that combine traction, aesthetics, and maintenance.

Site Grading Essentials

Prior to concrete placement, proper site grading establishes the foundation for a long-lasting, regulation-compliant driveway. The existing grade levels are checked, establish final grade levels, and create proper drainage angles-usually 2%-to guide water away from structures and toward approved outlets. You shape the subgrade to remove depressions, then perform soil compaction to required compression levels, confirming results with field tests. Stable subgrade prevents subsidence, cracks, and water accumulation.

We position drainage swales along the edges to collect runoff, linking them with approved collection points as per municipal requirements. Surrounding areas are secured by regulating drainage and mitigating washout with erosion barriers. Adequate distances are kept around garages, sidewalks, and utilities, while confirming setback distances. With elevation levels set, site review and marking comes before base preparation and concrete scheduling.

Strengthening and Surface Treatments

Once grades are verified and subgrade stability is confirmed, determine reinforcement and surface treatments that comply with Highland Park standards and project load requirements. Select #4 or #5 bars at 18-inch centers, or welded wire mesh per specifications, and fasten junction points to maintain proper cover. Reinforcement must maintain a minimum 2 inches of bottom cover and clear spacing from expansion joints, utilities, and driveway apron dowels. Install appropriate chairs, not stones, to elevate reinforcement. Anchor driveway-to-garage junctions with epoxied dowels when needed.

Install concrete at the designated slump, compact edges, and form control joints at 10-12 feet spacing or 24-30 times slab thickness within a 6-12 hour window. Apply finishing techniques that improve traction and durability: textured broom finish on drive areas, borders with troweled-and-broom finish, and curing compound or wet cure for a seven-day period.

Pool Decks, Patios, and Outdoor Entertainment Areas

You desire lasting outdoor spaces that look clean and function throughout the year. We utilize durable patio materials-concrete reinforcement, fiber additives, and protective sealants-to prevent UV damage, stains, and surface cracking. For swimming pool surrounds, we install anti-slip texturing and coatings that improve wet-condition grip without sacrificing comfort or drainage.

Resilient Patio Materials

Stone, concrete, and composite materials form the foundation of outdoor living spaces, pool surrounds, and patios that have to resist weather, traffic, and seasonal changes. It's essential to use materials that offer demonstrated strength and environmental protection. Choose concrete with air entrainment and fiber additives and proper base preparation to minimize deterioration. Install durable interlocking pavers with specialized joint sand to manage drainage. Select sustainable composite materials featuring sustainable materials with UV inhibitors that resist degradation or need frequent maintenance.

Set up adequate drainage through 1/8-1/4 inch per foot decline extending from structures, including perimeter edging and geotextile separation over compacted aggregate. Select sealers specifically rated for resisting deicing salts and UV exposure. Require ASTM/ACI compliance and documented warranties to guarantee reliable long-term performance.

Non-Slip Pool Decks

Besides structural integrity, poolside hardscapes must protect barefoot traffic from slips. The deck surface must combine safety compliance with attractive design. We select non-slip surface treatments with measured coefficient-of-friction values, use specialized surface treatments for reliable grip when wet, and refine joint layouts to minimize trip points. We incorporate water management systems-proper slopes, trench drains, and discreet channeling-to facilitate swift water drainage and reduce algae growth.

Our products include UV-stable sealers that resist chlorine and salt, plus heat-resistant materials that limit heat absorption. We restore spalls, resurface worn concrete, and apply broadcast aggregates where extra traction is required. Control joints, coping modifications, and handrail anchors are secured per code. The final product is a low-maintenance, protected, and beautiful pool deck engineered for daily use.

Walkways, Sidewalks, and Property Enhancement Solutions

An uneven or broken pathway can decrease your property's appearance and safety, expertly constructed paths and walkways directly improve visual appeal and practicality. We assess slope, water flow, and Highland Park building codes, then install appropriate base, framework, support, and expansion joints for sturdy, trip-free surfaces. You have the option of broom, exposed aggregate, or stamped finishes that balance traction and style.

To enhance visibility and compliance, we add precise curb painting at intersections and ADA-compliant ramps where needed. Well-planned landscaping elements create clear boundaries, protect concrete from soil erosion, and guide pedestrian traffic. Low-profile illumination, properly sealed edges, and properly spaced expansion gaps ensure easy maintenance. You obtain a unified entrance sequence that guides visitors, resists environmental wear, and enhances your property's curb appeal without overbuilding.

Structural Concrete, Foundations, and Slabs

Whether you're constructing new foundations or stabilizing existing structures, we specialize in designing and pouring foundations and slabs that fully comply with Highland Park codes, soil conditions, and structural loads. We comprehensively review geotechnical reports, recommend appropriate soil stabilization as required, and outline the appropriate rebar, post-tensioning, or grade beams to effectively manage movement and cracking. You'll receive precise elevations, vapor barriers, and strategically positioned control joints following ASTM and ACI standards.

For slabs-on-grade, we evaluate soil compaction, moisture barriers, and drainage patterns from the foundation. We select concrete mixes for strength, durability, and freeze-thaw resistance, and we oversee curing conditions to reach target PSI ratings. In basement and structural applications, we install formwork, anchor bolts, and dowels according to specifications. We include thermal barriers where needed, optimizing energy conservation while maintaining structural strength.

Custom Concrete Finishes: Stamped, Stained, and Polished Surfaces

From entryways to outdoor living spaces, you can elevate concrete with stamped, stained, or polished finishes that align with Highland Park standards and performance expectations. You'll pick profiles, aggregates, and slip-resistant coefficients that meet local requirements and use zones.

In stamped concrete applications, we establish precise mix formulations, joint placement, and textural details to replicate stone, brick, or wood while preserving proper water drainage and cold-weather resistance. Color integration and protective sealing maintain color integrity and prevent sun fading.

For stained floor surfaces, we evaluate moisture content in the substrate, choose between acid or water-based systems, and utilize densifying agents for better abrasion resistance. All edges and transition points are maintained in accordance with ADA requirements.

In polished concrete applications, we establish detailed cutting sequences, image clarity goals, and protective measures. This results in a long-lasting, simple-to-maintain surface that delivers both function and sophistication.

Repair, Resurfacing, and Maintenance Services

Even small surface defects can develop into serious structural concerns if ignored, so we meticulously identify underlying problems and implement code-compliant repairs customized for Highland Park specifications. We reinforce substrates, rebuild profiles, and reinstate proper drainage to protect adjacent structures and utilities. For tight, non-moving fractures, we apply crack injection to reestablish monolithic performance and stop moisture infiltration. Where material separation appears, we prepare and reconstruct with bonded overlays, ensuring correct slopes and control-joint configuration.

You'll receive a maintenance schedule that encompasses joint cleaning, sealant replacement, targeted patching, and seal coating to prevent damaging elements and wear. We maintain detailed records of all maintenance activities, offer warranty coverage, and verify compliance with city requirements. Our methodical process prolongs durability and reduces lifecycle costs.

Construction Materials, Techniques, and Weather Preparedness

These upkeep protocols deliver optimal results when you match them to the right mix designs, placement methods, and weather controls designed for Highland Park. Initial requirements include air-entrained mixtures with reduced w/c ratios, SCMs for durability, and approved admixtures for setting time control. For structural elements, establish appropriate concrete cover and joint specifications per ACI 318 and ACI 360. Where cold formed concrete assemblies are detailed, synchronize anchor placement, curing methods, and fastener specifications to prevent cracking.

You apply temperature‑controlled subgrades, utilize vapor barriers as needed, and apply slip‑resistant textures. Hydration sheets, insulated forms, and climate-controlled environments maintain hydration within target ranges. You integrate thermal bridging mitigation in slabs, balconies, and edges through thermal breaks. Ice-melt restriction protocols, sealants, and sawcut timing minimize scaling and joint raveling.

Clear Scheduling, Pricing, and Project Updates

Predictable results stem from clear expectations, therefore we incorporate transparency into all steps: a thorough baseline schedule with key timeline markers, resource allocations, and quality control points; a comprehensive scope outlining inclusions/exclusions; and a detailed estimate connected with quantities, unit rates, and contingencies. You'll get precise estimates that outline assumptions, alternates, and allowances, so pricing corresponds to drawings, specs, and applicable codes. We publish a Gantt schedule and share real-time updates when external factors, inspections, or utility locates influence sequencing. You can access submittals, mix designs, and pour tickets in a shared log. We record RFIs, change orders, and field directives with effects to time and cost. Periodic check-ins verify progress, safety, testing, and punch action items-delivering accountable execution without surprises.

Common Inquiries

Can You Confirm Your Licensing, Bonding, and Insurance Status for Highland Park Work?

We maintain complete licensing, bonding, and insurance coverage for Highland Park. We provide licensed professionals who know local codes and permitting processes. Upon request, we'll share our insurance and bond documentation, including license numbers for verification. We maintain general liability and workers' compensation coverage, and you'll be added as a certificate holder. Our credentials can be verified through city and state databases. We prioritize compliance, safety, and transparent documentation.

What Material and Workmanship Warranties Are Available

You receive explicit Material guarantees and Workmanship assurance. Test the concept: comprehensive warranties reflect our dedication. We back materials based on manufacturer terms-generally 2-5 years-fully documented and transferable as appropriate. We provide a 1-year warranty, protecting against workmanship and finish issues, in compliance with local codes and ASTM standards. We'll provide complete warranty certificates, containing start dates, exclusions, and claim procedures. If problems occur, reach out to our team; we'll assess, fix, and confirm proper resolution.

How Are City Permits and Inspections Managed?

We take care of all necessary permits and required inspections for you. We develop plans that meet all codes, process permit applications, and track permit processing with the city. We arrange scheduling of inspections, meet with inspectors onsite, and resolve any comments quickly. You'll get notifications at every key milestone-submission, authorization, pre-pour, and completion. Should modifications be necessary, we promptly issue updated documents. We ensure updated all necessary permits and insurance the city requires, guaranteeing your project proceeds smoothly and according to regulations.

Do You Have Local References and Recent Project Photos?

Yes. We'll provide a carefully selected list of current projects within 5 miles, complete with dates, scopes, and client testimonials. Since 63% of homeowners regret hiring without seeing proof, we showcase detailed project photos, before-and-after sets, and material specs. We offer contactable references, permit numbers, and inspection approvals for verification. Upon request, we can arrange site walk-throughs and deliver a secure link to a collection arranged by project type, code requirements, and finish options.

What Are Your Policies Regarding Change Orders and Unexpected Situations?

We issue documented modifications for any scope adjustments, with clear pricing and approved by you before proceeding with work. Unanticipated problems trigger contingency planning: we assess underlying factors, suggest conforming fixes, adjust timeframes and expenses, and document all changes. Should circumstances compromise safety or structural integrity, we halt operations until you approve the solution. We track variances, record daily progress, and manage inspection scheduling to ensure project control, compliance, and predictability.

Summary

You've got goals for your property, and we've got the concrete solutions to get you there. From driveways to decorative finishes, you'll benefit from regional experience, proven methods, and weather-resistant approaches. We take care of planning, implementation, and upkeep with clear schedules, transparent pricing, and regular correspondence-no guesswork. Whether it's a new foundation or a refined outdoor space, we maintain quality throughout. Let's transform your vision into reality-strong as bedrock, smooth as a well-set finish.